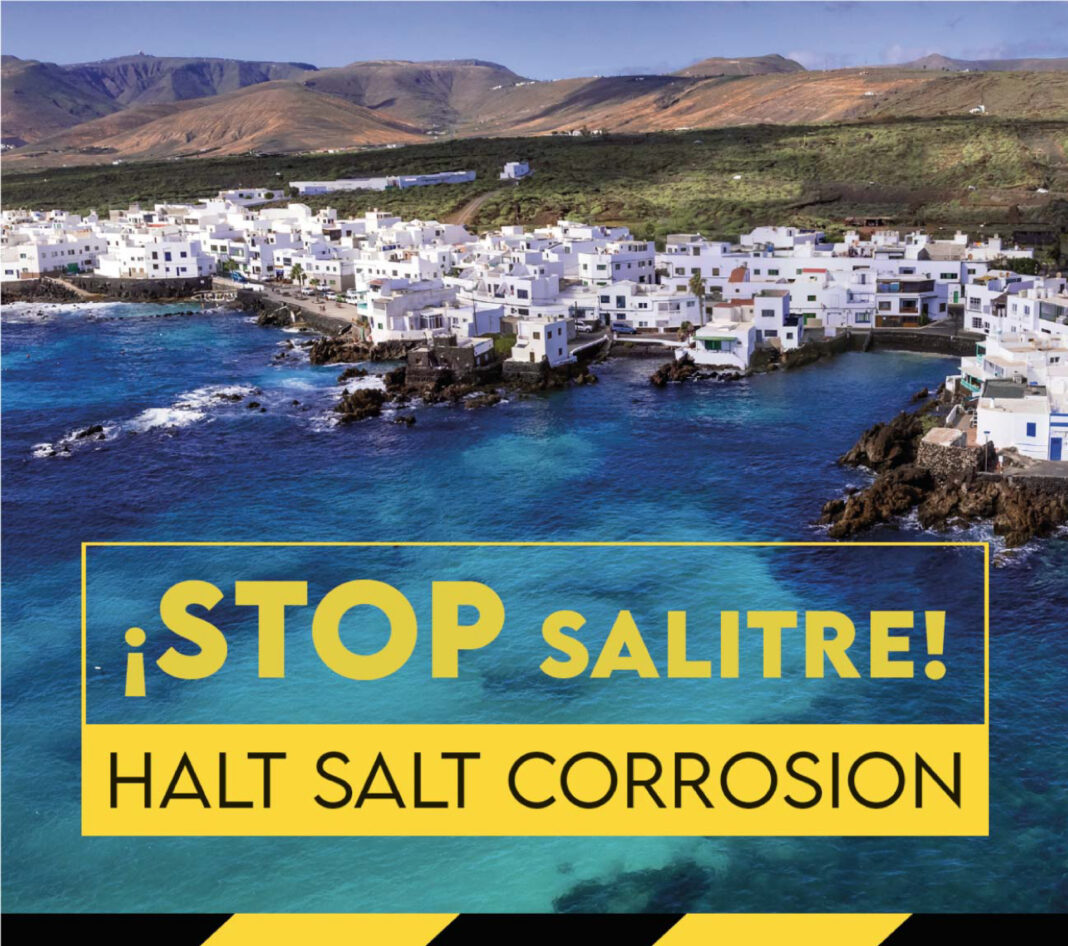

A team from the Universitat Politècnica de València (UPV) has successfully developed a tool designed to extend the service life of buildings and infrastructure located near the coast. This system facilitates analysis and comparison of different construction materials and techniques and calculates how frequently maintenance work is required. The study examines how, and to what extent, marine air exposure accelerates the corrosion of concrete and reduces a structure’s durability.

The key lies in cement type, which is critical for both new builds and repair operations. Sulphate-resistant Portland cement (CEM I SR) provides the most effective foundation in marine environments. It prevents the chemical reactions that cause the concrete to crack when exposed to saline soils or water. Long established in public works, its use is increasingly common in coastal construction. Silica fume is an effective admixture as its ultra-fine particles densify the cement paste, thereby reducing porosity and significantly boosting protection against chlorides, the primary cause of steel rebar corrosion.

These materials are not only compatible but also complementary. The CEM I SR blocks the destructive attack of sulphates, while the silica fume limits the penetration of salts. Used together, they offer a double barrier that is ideal for marine zones, whether in new constructions or renovation and restoration projects.